For the development of powerful brake functions and a unique brake feel

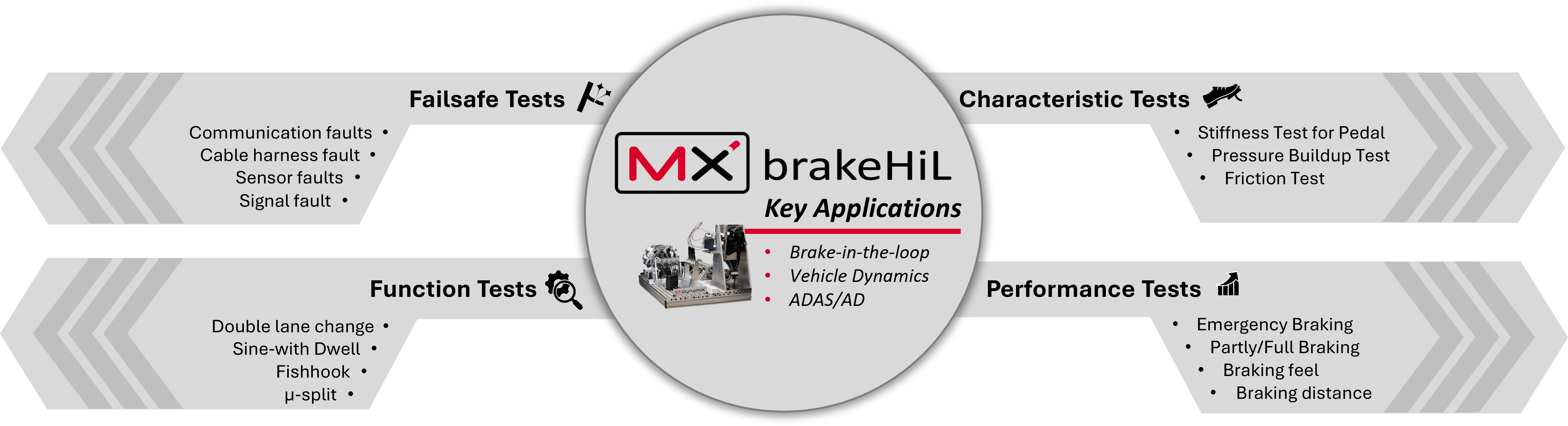

MXbrakeHiL: Test, evaluate, and apply ESC ECU and vehicle control functions

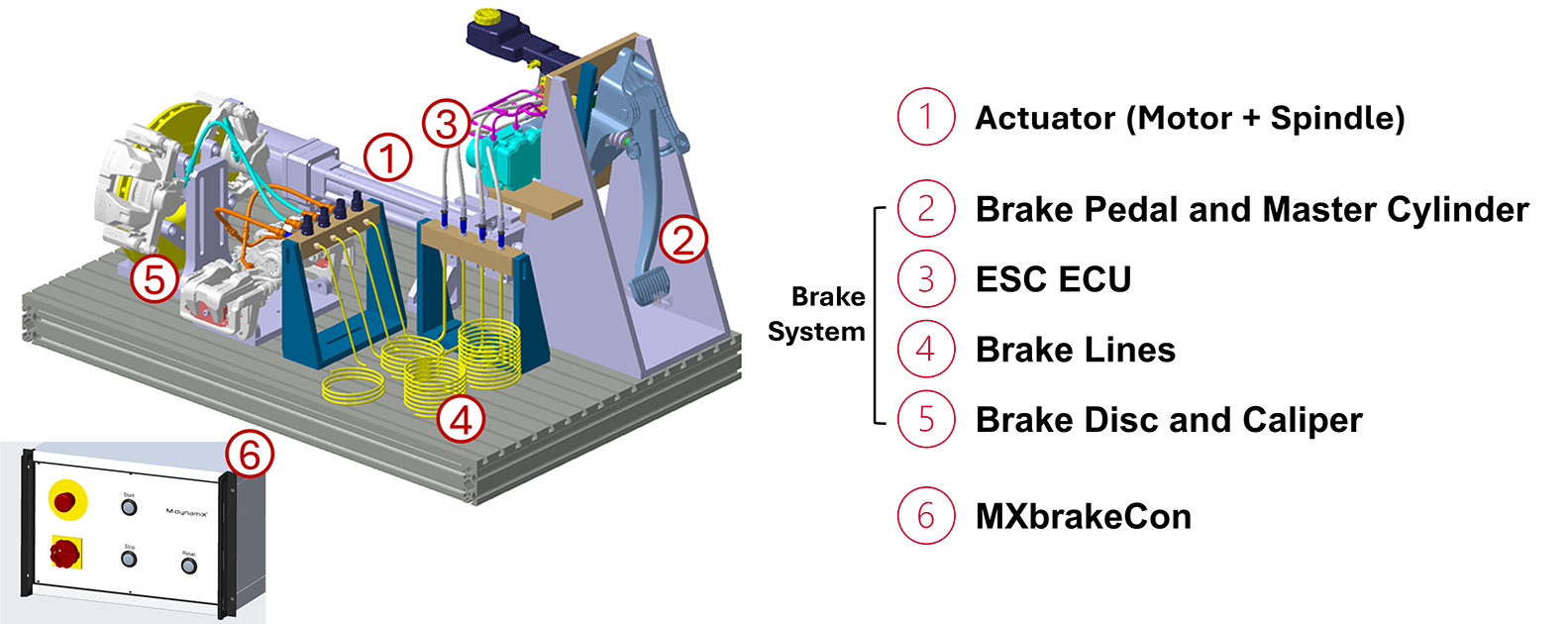

The cutting-edge brake system test bench, MXbrakeHiL, is designed specifically for the growing needs of electric and automated vehicles. The test bench system is versatile, compatible with various real-time systems, and optimized for model-based development of ESC ECUs and advanced safety functions. Integration of the full hydraulic/ electromechanical brake system into the real-time environment, from the pedal to the brake calipers. This strongly reduces simulation complexity, simplifying development and validation tasks in every technology readiness level.

Key Applications

Key facts

- Versatile integration into the real-time system and vehicle model

- Realistic testing and developing of the whole braking system

- Development of braking functions and braking feel

- Optimized for model-based development

- Compatibility with dynamic and static driving simulators

- Requirements-based testing in the systems engineering process

- Integrated evaluation tool MXeval for objective KPI based analysis

MXbrakeHiL – structure

Why MXbrakeHiL?

Realistic and accurate testing of braking systems

The MXbrakeHiL allows testing of ESC ECU performance, AEB functionality, or other safety features of braking systems under realistic and accurate conditions. It can simulate different scenarios, such as road surfaces, vehicle speeds, braking forces, and environmental factors, using our advanced software models and hardware components.

Flexible and versatile configuration

Configure it to suit your specific needs with your own sensors, actuators, and components, or use our universal modules to emulate them. The test bench can be connected to most real-time systems and vehicle models, such as Vector DYNA4, IPG CarMaker, dSpace ASM or other solutions like self-developed MATLAB/Simulink models.

Efficient and cost-effective development process

By testing and validating your braking system in every stage of the development process, time and cost is reduced. Optimize your design parameters, identify and correct functional errors before touching the proving ground, and thus improve your product quality and reliability.

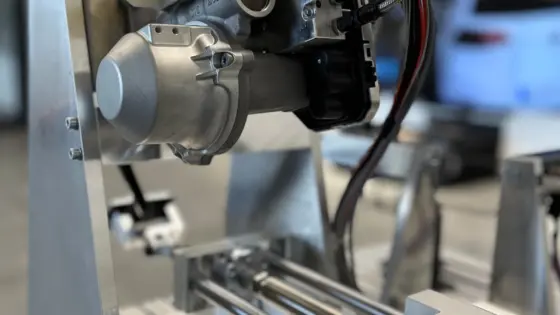

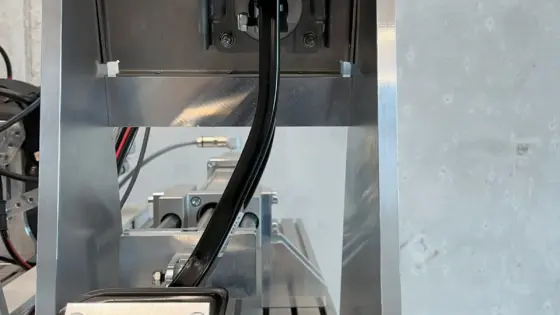

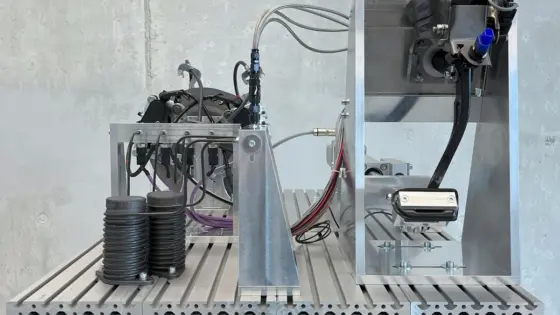

MXbrakeHiL Impressions

Convince yourself

Contact us now and test our systems free of charge and without obligation. Move your test drives from the road to your office and convince yourself of our performance:

Test it, Feel it, Brake it.